Search

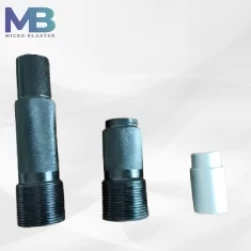

Boron Carbide Nozzles

We sell a wide variety of Boron Carbide Nozzles to meet the diverse criteria of the employers. We produce the provided carbide nozzles from high-quality raw materials, obtained from the industry's most authentic suppliers while keeping international quality standards in mind.

Product Details:

| Material | Boron Carbide |

| Air Consumption | 12-120 Cfm |

| Finishing | Smooth |

| Air Inlet | 7kg |

| Hardness | 9 |

| Brand | Sand blasting Hopper |

Blasting Nozzle

We manufacture a large range of Best quality Blasting Nozzles with our industry experience. The range offered includes boron carbide nozzle, tungsten carbide, and carbide nozzles of silicon. Providing the best quality raw material from the most reputable suppliers in the market, customers greatly enjoy our offer. In addition, these nozzles are manufactured in accordance with the patron's specifications.

Boron Carbide Nozzles

We sell a wide variety of Boron Carbide Nozzles to meet the diverse criteria of the employers. We produce the provided carbide nozzles from high-quality raw materials, obtained from the industry's most authentic suppliers while keeping international quality standards in mind. After manufacturing, we pass a consistency test for the provided carbide nozzles to ensure they meet our expected quality standards.

The durability of boron carbide nozzles provides excellent cost advantages in the blasting phase. Boron carbide nozzles, due to their high hardness, had a long service life. In manufacturing settings, boron carbide is more demanding because of its higher hardness, less wear, and long service life.

Boron carbide is a Venturi-type nozzle with high removal rates due to the combination of high blast media acceleration and low air use. A Venturi boron carbide nozzle style is used during the blasting procedure for wide-area preparation. Boron carbide nozzle has continuous working performance and uniform blasting. Venturi nozzle form consists of converging inputs and diverging outputs. As a result, the blasting process continues to cover more areas. The combination of blasting media and compressed air also increases movement.

High-performance boron carbide nozzle with a wide range of blasting media included. By minimally enlarging the bore the dust absorbs low air. In stressful applications, this dust offers minimal wear.

Specification of Nozzle

Boron Carbide Nozzles are less in weight as compared with tungsten carbide nozzles. Bore carbide nozzles are used on the head because of their lightweight inner pipe blasting method. Owing to the light boron carbide dung it is simple for the user to carry out a blasting procedure as the tool head rotates when blasting begins. Boron carbide nozzles are available as needed in various sizes. Compressed air is used for the sand blasting process.

The scale of the jet depends on the power of the air compressor. Various nozzle sizes have varying cleaning speeds for the surface of the part. One of the most critical parts and a suitable or inadequate blast nozzle affects the output rate in the blasting machine. The rate of production depends on the scale of the piston and the supply of compressed air.

Features of Boron Carbide Nozzle

- Boron Carbide Nozzle Benefits

- Longer life span.

- High durability.

- High ability to withstand wear.

- Anti-corrosion treatment.

- Low cost peruse.

- Downtime reduction

Uses of Boron Carbide Sandblasting Nozzles

- Ballistic armor

- Armor of the body

- Tooling Ceramic

- Tools for cutting

- Blast Cleaning

Boron Carbide is highly resistant to abrasive wear due to its high durability. Certain uses include slurry pumping dots, blast washing, and jet cutters for water.

Boron Carbide Nozzles Manufacturer in India

Sand Blasting Hopper is the leading Boron Carbide Nozzle Manufacturer In India. Our bulking system is able to blast media and compressed air differently. The Boron Carbide Nozzles sizes are often modified by the capability of the unit type. Different models of machines have different storage capacities and requirements for compressed air are different. The system model capability also affects the sand dump and cleaning rate. We are also manufacturing top-quality shot blasting machines, metalizing wires, shot blasting cabinets, grit blasting machines, thermal spray guns, and many more products at the most affordable prices in Jodhpur, India.

Boron Carbide Nozzle Prices in India

Contact info@sandblastinghopper.in or either 8003997469 to know the latest Boron Carbide Nozzles Prices in India. We are the leading Carbide Nozzles Manufacturers in India. Also check the prices of Bentonite Plants, Centrifugal Fans, Paint booth and etc.